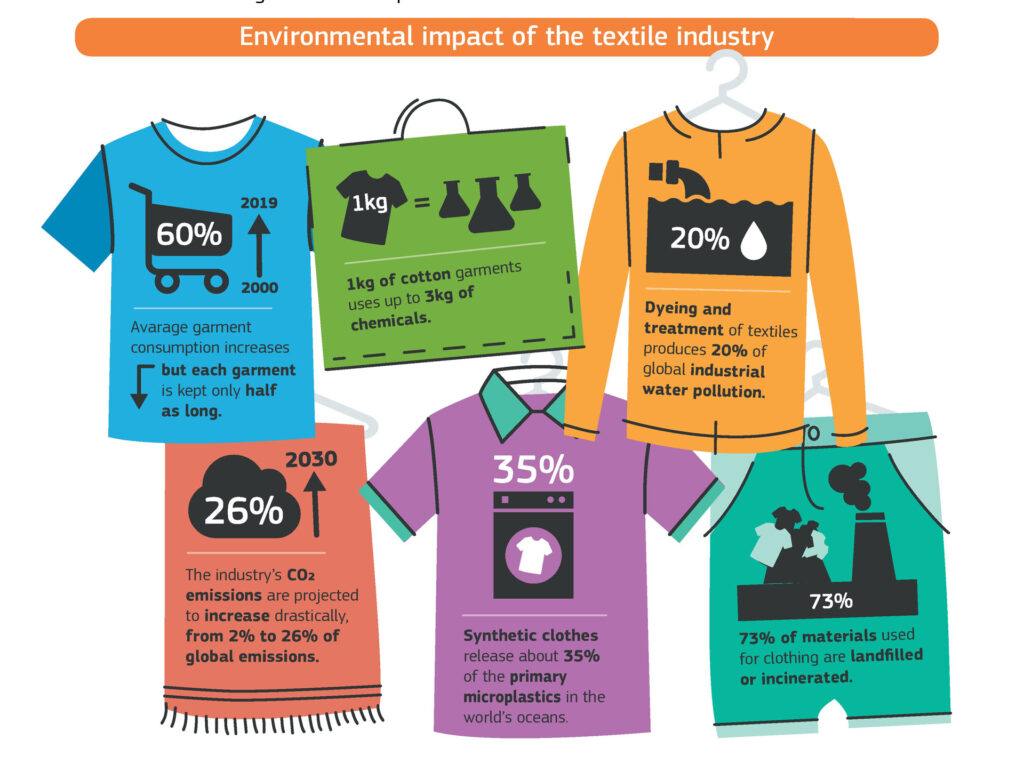

The textile industry has an unsustainable environmental footprint (Fig. 1). It is a highly resource-intensive and waste-generating sector, contributing—depending on the source—between 3% and 10% of global CO2 emissions [United Nations sustainable development goals (2019)], or 1.2 billion tons of CO2 annually. This is more than the combined emissions from all international flights and maritime shipping.

Despite ongoing discussions about environmental sustainability, synthetic polyester fibers have seen the most significant growth in recent decades. However, these fibers have poor biodegradability, with some estimates suggesting they take up to 50 years to break down in nature, compared to natural, renewable fibers like cotton, which degrades within months.

There is growing awareness of the presence of microplastics in the environment, with textiles made from synthetic fibers like polyester recognized as a significant source. The wearing and washing of these textiles release microplastics into the environment.

The shift towards polyester, coupled with the rise of fast fashion over the last 20 years, has further exacerbated the industry’s environmental impact.

Policy Changes in the EU could be a Game Changer for Textile Recycling

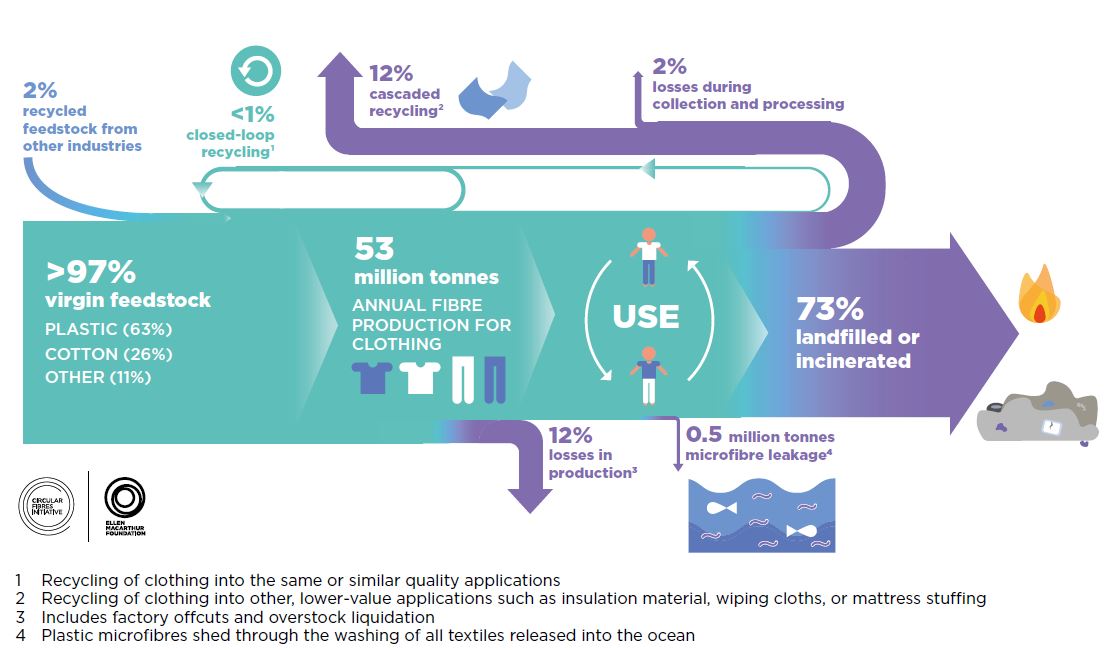

In the European Union, each person generates 12 kg of clothing and footwear waste annually. A significant portion of these textiles is either incinerated or sent to landfills after use, with only about one-fifth of post-consumer textile waste being collected for reuse or recycling (European Parliament: Waste framework directive: A more sustainable use of natural resources (2023))

To tackle these challenges, the EU Commission is proposing new regulations to make producers responsible for the entire lifecycle of textile products and to establish a legal framework for sustainable textile management. The goal is to introduce mandatory Extended Producer Responsibility (EPR) schemes for textiles across all EU member states. The Commission’s vision for 2030 [European commission: EU Strategy for Sustainable and Circular Textiles (2022)] is that all textile products sold in the EU will be “durable, repairable, and recyclable, largely made from recycled fibers, free of hazardous substances, and produced in a way that respects social rights and the environment,” effectively bringing an end to fast fashion.

Circular Economy for Textiles

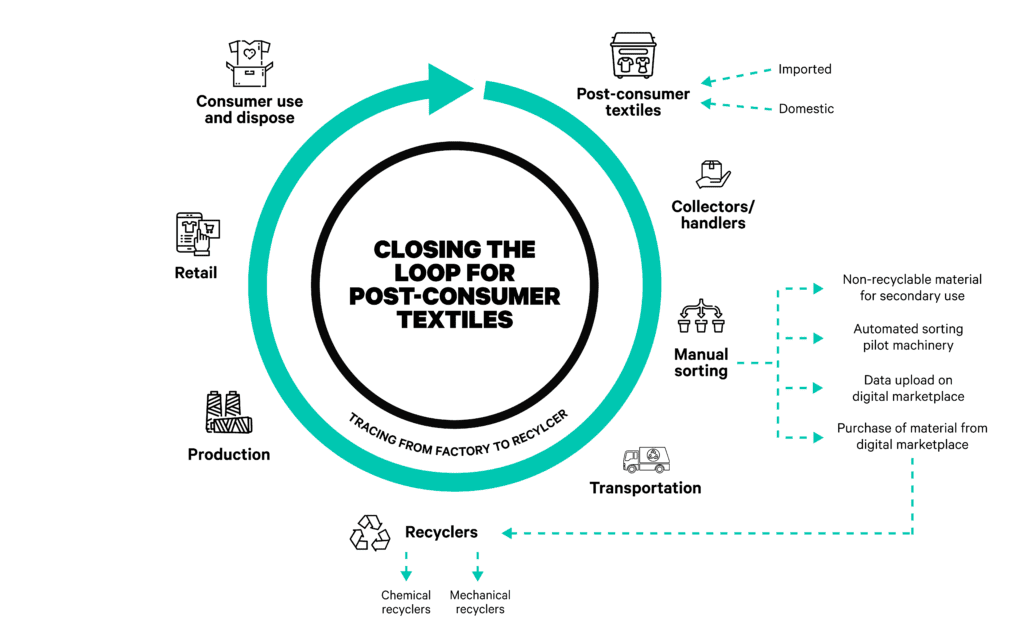

The ultimate goal is to establish a circular economy in the textile industry, where textile waste is recycled and repurposed as raw material for creating new textiles (Fig. 2). Currently, only a small percentage of textiles are recycled in a closed-loop system. According to a 2015 white paper by the Ellen MacArthur Foundation, a think tank advocating for the circular economy, the figure was as low as 1% (Fig. 3). Despite significant research, development, and pilot projects over the past decade, large-scale industrial implementation remains in its early stages.

Industrial Activities to Address Textile Recycling

We are still far from realizing the vision set forth by EU policymakers. This is primarily due to the high complexity and numerous technical challenges involved, which result in costly processing. When legal requirements are fully enforced, a new recycling industry will need to be established and scaled up significantly.

A 2022 McKinsey study estimates that by 2030, 18-26% of textile waste could be recycled into new clothing, potentially creating 15,000 new jobs in Europe. However, achieving this would require substantial capital investment, estimated at 6-7 billion euros. Given the current state of development in 2024, this timeline seems unrealistic. The process is still in its infancy, though several startup companies, such as Evrnu, Renewcel, Worn Again, Spinnova, and SuperCircle, have made promising advancements.

The transition to a circular economy is challenging. Funding and profitability are major obstacles, as highlighted by the recent bankruptcy filing of the Swedish company Renewcell. Scaling up from lab-based solutions to full industrial manufacturing takes time and demands significant investment, with payback periods much longer than typical investment cycles.

Technical Challenges and how they are Addressed

Part 2 of this article delves deeper into the emerging technologies and innovations driving textile recycling towards circularity. It explores the challenges and opportunities within the industry, highlighting key players, the necessary infrastructural shifts, and the regulatory landscape essential for achieving a sustainable and scalable textile recycling ecosystem.