The textile industry is notorious for high CO2 emissions, largely due to its significant energy consumption and reliance on various energy sources. This article dives into the energy consumption patterns of the textile sector, its contribution to global CO2 emissions, and explores strategies for reducing its carbon footprint through innovative technologies and processes, specifically focusing on increasing energy efficiency and reducing CO2 emissions in dyeing and finishing processes.

High Energy Consumption in the Textile Industry

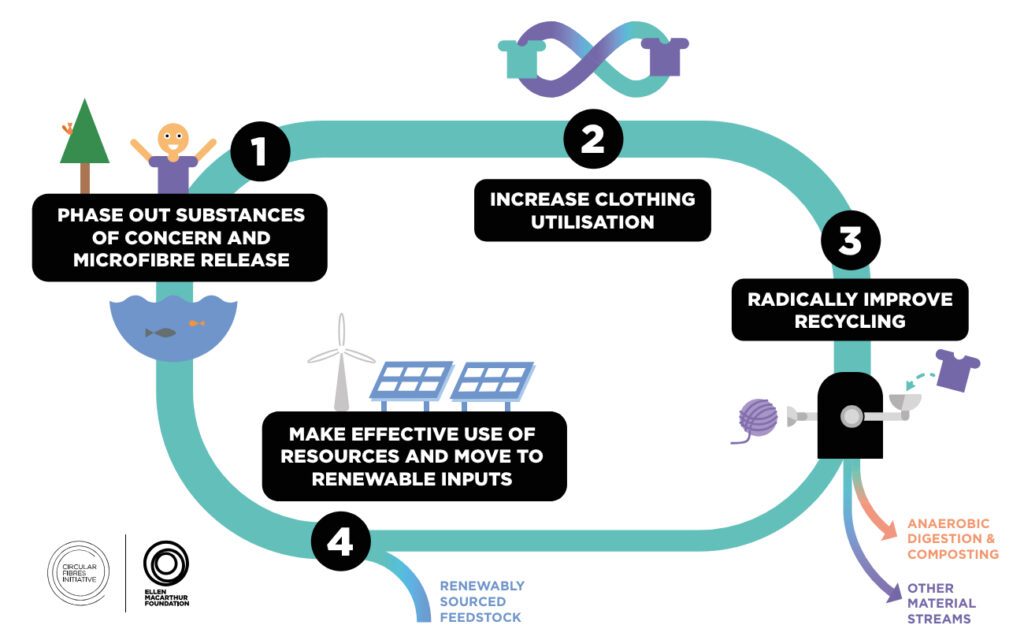

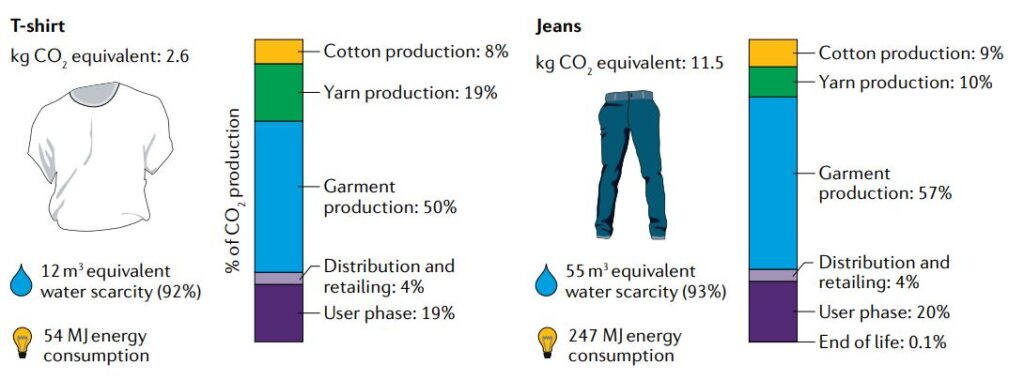

The textile industry is a major consumer of energy, which translates into a significant share of global CO2 emissions[1]. NGO and policymakers claim up to of global CO2 10% would be due to the textile industry whereas the carbon budget would be only 2% to meet the 2 degrees global warming scenario. Measures are required “to make effective use of resources and move to renewable inputs “, according to Ellen MacArthur foundation (Figure 1[2]). Examples are given in Figure 2 on the environmental footprint of a T-shirt and a pair of jeans.

Understanding the energy mix, and its impact on CO2 emissions, is crucial for identifying reduction opportunities.

CO2 Emissions by Various Energy Sources

The primary energy sources include coal, oil, natural gas, nuclear and renewables such as hydro and solar power [3]

- Coal (0,094 kg CO2/MJ = 338 g CO2 / KWh): high CO2 emissions per unit of energy

- Oil (0,074 kg CO2/MJ = 266 g CO2/KWh): similar to coal, oil contributes significantly to CO2 emissions

- Natural gas (0,056 kg CO2/MJ = 202 g CO2/KWh): Lower emissions than coal and oil, but still substantial

- Nuclear and renewables (hydro, solar and wind power) have minimal CO2 emissions (< 1 CO2/KWh)

Thus, by changing to energy mix to a more favorable energy supply will substantially reduce CO2 emissions, e.g. from coal to natural gas by 40%, and theoretically almost to nil by nuclear or renewables.

Energy Mix in Key Textile Manufacturing Countries

The energy mix in major textile manufacturing countries varies by country, e.g. in China, India, Pakistan, Bangladesh, and Turkey energy predominantly depends on fossil fuels like coal and oil [4]. CO2 emission at the present energy mix is estimated 230-280 g CO2 per KWh.

In the traditional markets in Europe, due to a higher share of non-fossil energy sources, CO2 emissions by energy units are lower, estimated 50-150 kg CO2 per KWh.

It is important to look at the specific energy setup at a particular mill to judge on the CO2 footprint which varies from case to case.

CO2 Emissions of Various Textile Fibres

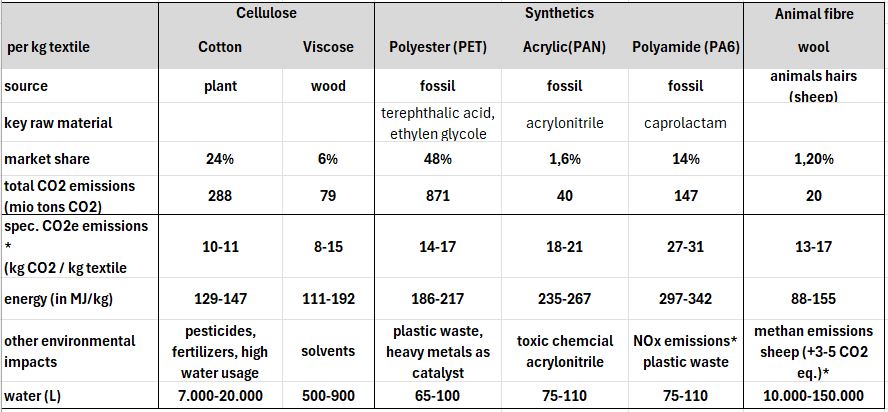

Different fibres in textile materials contribute differently to CO2 emissions based on their energy consumption (Table 1).

As of recent estimates, the global CO2 emissions from all anthropogenic (human-made) activities are approximately 36.8 gigatons (Gt) per year[5], of which textile manufacturing is estimated 1.5 Gt CO2 (~ 4%); the usually quoted 10% contribution includes the total lifecycle of the textiles. The table shows the drill down to individual fibres and their contribution. By far the highest share has polyester, due to the fact that it is the biggest fibre in the market and it has above average CO2 emission, being a synthetic fibre that generally have a higher contribution per kg of textile (polyester, polyamide, acrylic).

Cotton has lower CO2 emissions compared to synthetic fibres. However, its very high water consumption due to irrigation is a major concern. This depends on the origin of the cotton, therefore the high spread in the values.

Polyester (PET), the biggest fibre by its market share, has a high energy consumption and therefore high CO2 emissions, however recycling concepts such as using recycled PET bottles as raw material source can mitigate this.

The numbers in Table 1 on the per kg energy consumptions were collected from various literature and modified with own calculations on CO2 emissions, since not all data are consistent. CO2e includes the impact from other greenhouse gases such as methane from sheep and NOx in polyamide.

Energy and Emissions in Dyeing Processes

Cotton Dyeing

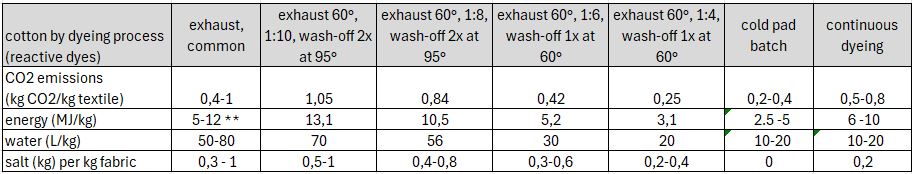

Exhaust dyeing variations can have a significant impact on energy consumption and CO2 emissions. Lowering the temperature in the wash-off, for example, from 95°C to 60°C, and reducing the washing baths, can considerably reduce energy use and emissions. This reduction is possible through the use of special dyes designed for effectiveness at these lower temperatures. Additionally, adjusting the liquor ratios in the dyeing process can lead to substantial resource savings. Shorter liquor ratios are more efficient, and modern machinery operate with a liquor ratio of 1:5 or even less. Common in the market is a liquor ratio 1:6 to 1:8. A liquor ratio reduction also reduces the salt load.

These options cut down on energy and water consumption, making the entire process more environmentally friendly. Table 2 shows data for typical setups.

Comparing semi continuous and continuous dyeing with traditional exhaust dyeing reveals further benefits in terms of energy and emissions. Semi continuous dyeing such as cold pad batch generates fewer CO2 emissions and requires less energy and less water. Continuous dyeing, illustrated in the table for Pad Dry Chemical Pad Steam, is higher, due to steaming and intermediate drying.

In particular, cold pad batch enhances environmental sustainability, making it a preferred choice for textile manufacturers aiming to reduce their carbon and water footprint, provided the machinery setup is compatible with fabric constructions (mostly for woven, but growing for knit ware as well). Traditionally a European process, where batch sizes are smaller, it increasingly penetrates the markets in Asia as well.

Benninger, the Swiss textile machinery maker, claims to reduction the CO2 footprint from exhaust jet dyeing to Benninger CPB to 38% [6]. They also claim to achieve a stunningly negative CO2 footprint by full implementation at Lenzing´s viscose factory in Austria.

Polyester Dyeing

In exhaust dyeing, although the polyester dyeing temperature of 130°C is much higher than for cotton, the energy usage remains comparable, at 6-10 MJ/kg, due to the reduced amount of water required for washing.

Dyeing from supercritical CO2 dyeing is an innovative method that significantly reduces CO2 emissions in the dyeing process and it is basically waterless. Market penetration of this technology is still low, due to high capital expenditure for the investment and incomplete dyes availability.

It should be stressed that polyester is burdened by inherently high energy requirements, since it is made from fossil sources. The dyeing part contributes a comparably low fraction to this. Emission reductions in the dyeing process still doesn´t make it overall sustainable, and it does not solve the issue of plastic waste. Further implementation of recycling practices are required to realize the environmental benefits of innovative polyester dyeing technologies.

State of the Art and Innovations in Machinery

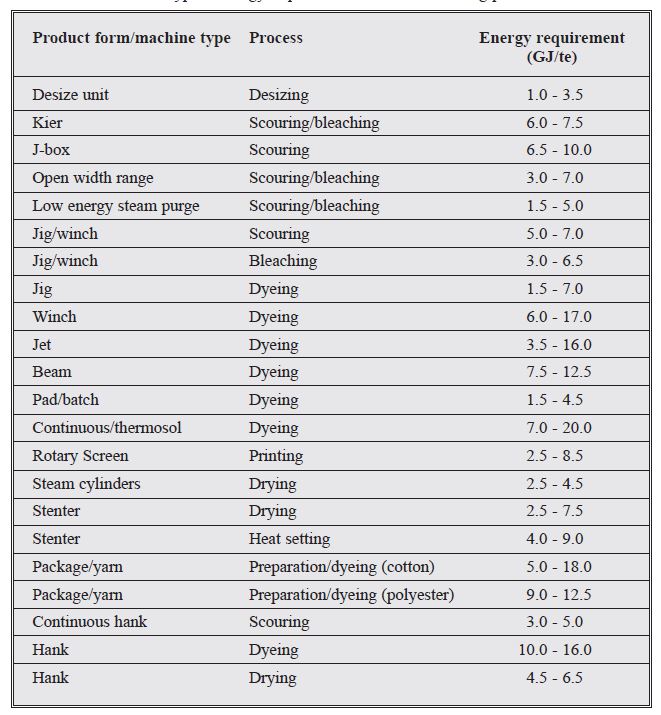

Technological innovations in dyeing and finishing machinery are crucial for minimizing the textile industry’s carbon footprint. The typical energy requirement by textile machines is shown in Figure 3.

Modern machinery, such as low liquor ratio jets, dramatically reduces water and energy consumption. Low liquor ratio jet dyeing machines, including the Thies iMaster H2O, Fong’s TEC Series, Sclavos Venus, Obem StarFlow, and MCS Jiggers, are engineered for efficient dyeing of cotton and polyester fabrics. These machines feature liquor ratios as low as 1:3.5 to 1:4, ensuring minimal water, energy, and chemical usage. They provide uniform dyeing with high reproducibility, thanks to advanced control systems and optimized circulation. These technologies emphasize eco-friendly operations, aligning with contemporary sustainability standards. By reducing resource consumption and improving dyeing precision, these machines represent a significant advancement in the textile industry’s efforts toward environmental responsibility.

Thies launched its innovative Signature Series at ITMA 2023 in Milano (Figure 4). This new dyeing technology offers ultra-low liquor ratios starting at 1:2.3, significantly reducing water and dye consumption. The machine enhances dyeing uniformity and shortens batch times, providing a sustainable solution for various fabric types with advanced digital control systems.

Another example for machinery innovation is Alchemie´s waterless Endeavour system. Jsrtex, a textile manufacturing company based in Taiwan has completed its first sustainable dye run, which uses 95% less water and 85% less energy, according to Alchemie [7].

In continuous and semi-continuous dyeing interesting innovations of recent years are spray dyeing and foam dyeing. WEKO, who acquired Rotaspray in 2021, combined the dye padding with a non-contact forced rotor spray application of the chemicals in the Pad-spray-steam process [8]. No intermediate drying is required, therefore saving energy and reducing CO2 emissions. An example for foam dyeing is the “Dry Indigo Denim” collection launched by

the denim brand Wrangler, which features foam-dyed denim fabrics produced by the Spanish mill Tejidos Royo. The dyeing process utilizes machines from the Gaston Systems based on a patented technique.

Strategies for Enhancing Energy Efficiency and Reducing CO2 Emissions

Adopting advanced dyeing techniques is essential for reducing energy use and CO2 emissions. Cold pad batch dyeing is more efficient compared to traditional exhaust dyeing, offering significant energy savings. In exhaust dyeing, the implementation of ultra lower liquor ratios cuts down water and energy consumption, making the dyeing process more sustainable.

Investing in modern machinery is crucial for achieving energy efficiency and reducing emissions. Upgrading to the latest dyeing and finishing equipment can result in substantial energy savings.

Selecting sustainable fibres is another important strategy. Natural fibres like cotton have lower CO2 emissions compared to synthetic fibres. However, the high water consumption associated with cotton farming remains as a handicap.

Intelligent selection of resource saving dyes and chemicals that require lower temperatures and less water further enhances the sustainability of textile production.

Implementing recycling practices is vital for mitigating the high energy costs associated with synthetic fibre production. Recycling polyester from PET bottles can significantly reduce energy consumption and CO2 emissions. Developing robust recycling systems within textile mills can help lower the overall environmental impact of the industry.

Optimizing process parameters can lead to significant resource savings. Lowering dyeing temperatures and reducing the number of soaping steps can save considerable amounts of energy. Efficient machinery operation and maintaining shorter liquor ratios contribute to enhanced resource efficiency and reduced environmental footprint.

By focusing on these areas, the textile industry can move towards a more sustainable future with reduced CO2 emissions and energy consumption.

Future Directions

The textile industry must continue to innovate and adopt best practices to achieve sustainability goals. Future research and development should focus on:

- Renewable Energy Integration: Increasing the share of renewable energy in textile manufacturing.

- Advanced Materials: Developing new fibres and materials with lower environmental impacts.

- Circular Economy Models: Promoting recycling and reuse within the industry to minimize waste and reduce energy consumption.

By committing to these strategies, the textile industry can play a pivotal role in combating climate change and promoting environmental sustainability.

[1] Niinimäki, K., Peters, G., Dahlbo, H., Perry, P., Rissanen, T., & Gwilt, A. (2020). The environmental price of fast fashion. Nature Reviews Earth & Environment, 1(3), 189-200

[2] Ellen MacArthur Foundation (2017). A New Textiles Economy: Redesigning Fashion’s Future

[3] https://www.volker-quaschning.de/datserv/CO2-spez/index_e.php

[4] variety of sources including academic articles, industry reports, and energy statistics from global institutions, evaluated with ChatGPT

[5] International Energy Agency, https://www.iea.org/reports/co2-emissions-in-2023

[6] Benninger brochure: Carbon footprint trail, https://benningergroup.com

[7] https://www.alchemietechnology.com/news/jsrtex-adopts-alchemies-dyeing-solution/

[8] Sanjal, J., “Less CO2 emissions: pad-spray-steam cotton dyeing”, ttps://www.wtin.com/article/2024/march/11-03-24/less-co2-emissions-pad-spray-steam-cotton-dyeing/

[9] Various sources, literature review supported by ChatGPT 4.0, https://oecotextiles.blog/2009/06/16/what-is-the-energy-profile-of-the-textile-industry/

[10] Shen, L., & Patel, M. K. (2008). Life cycle assessment of polysaccharide materials: A review. Journal of Cleaner Production, 16(2), 162-168.

[11] Rana, S., et al, “Carbon Footprint of Textile and Clothing Products”, Handbook of Sustainable Apparel Production, 1st edition, chapter 7, CRC Press (2015), 141-166

Unquestionably believe that which you said. Your favorite

justification appeared to be on the internet the simplest thing to be aware of.

I say to you, I definitely get annoyed while people think about worries that they

plainly do not know about. You managed to hit the nail upon the top and defined out the

whole thing without having side-effects , people could

take a signal. Will probably be back to get more.

Thanks

It’s very easy to find out any matter on web as compared to textbooks, as I

found this piece of writing at this site.