StepChange Innovations blog covers ecology issues

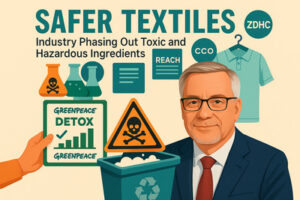

In recent years, the textile industry has come under growing pressure to address the environmental and health impacts of its chemical use. Legal regulations and demands from major international retailers have prompted significant changes in textile manufacturing processes. This article examines the efforts to reformulate and replace products in order to reduce toxicity and hazardous substances, with a focus on the influence of campaigns such as Greenpeace’s Detox initiative, the formation of industry groups like ZDHC, and the role of regulatory frameworks such as REACh. By exploring the strategies and challenges of this transition, the article highlights the progress made and the ongoing efforts to create a more sustainable and safer textile industry.

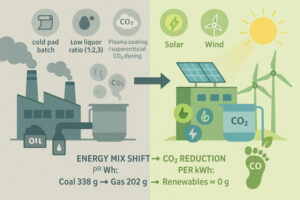

The textile industry is a major contributor to global CO₂ emissions due to its intensive energy use, particularly in dyeing and finishing processes. This article explores practical strategies and innovative technologies that can dramatically improve energy efficiency and lower the carbon footprint in textile production. From switching to renewable energy sources and optimizing dyeing methods, to adopting modern machinery and promoting recycling, the industry has numerous opportunities to enhance sustainability. Learn how leading-edge solutions are paving the way for a cleaner, greener future in textiles.

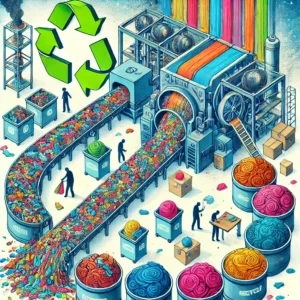

The textile industry is facing significant technical challenges as it transitions from a resource-intensive and polluting sector to a circular, sustainable model. Overcoming these hurdles requires advanced recycling technologies, substantial investments, and a shift in consumer habits. With the EU driving stricter sustainability regulations, the industry's ability to innovate and address these complex technical obstacles will be crucial for creating meaningful and lasting change.

The textile industry's environmental impact has worsened due to the rise of synthetic polyester fibers and fast fashion. These fibers are poorly biodegradable, contributing to long-term pollution. In the EU, 12 kg of textile waste per person is generated annually, with most being incinerated or landfilled. To combat this, the EU Commission proposes making producers responsible for the entire lifecycle of textiles and promoting a circular economy. However, large-scale recycling remains in its infancy, facing significant investment and technological challenges.

Hemp is discussed as a more sustainable alternative to cotton. There are many environmental advantages of hemp compared to cotton. However, the advantages are partly offset by various technical challenges.

In this article we cast light on the progress of the Detox campaign in the textile industry. Detox is an initiative started by the environmental activist organization Greenpeace to eliminate hazardous chemicals from the supply chain of global fashion brands. In part 2 we will look a deeper at the progress of Detox at the fashion brands who have received credit for good progress in Detox: H&M, Benetton and Zara (Inditex).

We cast light on the progress of the Detox campaign in the fashion & textile industry. Detox is an initiative started by Greenpeace to challenge the business practice of global fashion brands who source from suppliers allegedly polluting the environment with hazardous chemicals. Their aim is to eliminate the discharge of hazardous chemicals from the effluents of textile processing factories by the year 2020.

Dyeing in supercritical CO2 could finally be on track for success after 25 years of development. Originally an idea of German universities, it was developed and brought to market by the Dutch start-up company DyeCoo. With this innovative, environmentally friendly and water-free dyeing technology, today sportswear textiles made of polyester are produced in Asia for the brands of adidas and Nike.

Another brilliant example of a new material for camouflage colour effects, inspired by nature. Scientists at the University of California have created a thin, flexible material that changes colour when stretched or bent. It has potential for the future of camouflage,

Organic cotton and genetically modified cotton (GM cotton) are opposite concepts to make cotton more sustainable. In that sense it is the target to reduce water and energy consumption of cotton agriculture and processing, and to reduce the amount of potentially hazardous chemicals, such as pesticides, released into the environment.

A lot of totally contracting data can be found to support either one of the concepts, depending how things were examined and by whom studies were funded. This article tries to bring to light some of the issues related to cotton, GM and organic.