To read the full article, please login. The full content of this article and all premium articles is available exclusively for site members.

Site membership is free. If you are an existing user, please login. New users may register below.

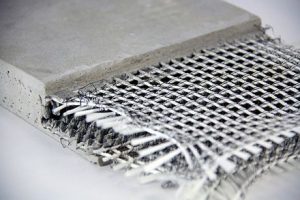

Graphene, the wonder material for a new industrial revolution?

Graphene, the wonder material for a new industrial revolution? Graphene has the reputation to be able to transform a range of sectors such as electronics, energy, health and construction, to revolutionize the fields in which they are applied. Many experts claim that graphene has the potential to become the material of the 21st century. Not a month passes without media and blogosphere reports on the “new wonder material”(1) Graphene properties Graphene has almost magic properties electrical conductivity superior to copper 200 times stronger than steel but six times lighter only absorbs 2% of light – almost perfectly transparent impermeable to gases, even to the smallest ones such as hydrogen or helium it can alter its properties by chemical derivatization on the surface These magic properties of graphene are the reason why scientists see enormous potential for future applications of graphene. Applications for the new “wonder material” Various science and technology fields could potentially face disruptive changes due to future graphene applications. A very comprehensive summary was given by Ferrari et al. (2) who laid out the European roadmap for graphene science and technology (3). Possible graphene applications (2) The science and technology fields related to graphene include health and environment, production, sensors, flexible electronics, energy conversion and storage, composite materials, biomedical devices, and electronic devices, including spintronics, photonics and optoelectronics. To understand the „magic“ properties of the new material one has to look at the chemical structure of the material. The structure of graphene Graphene is a modification of carbon, a two dimensional network of carbon atoms. Carbon has various modifications: The most prominent ones are diamond and graphite. Graphene is a single layer of graphite (see the appendix for structural details of diamond and graphite). How graphene is related to other carbon structures. Source: University of Erlangen, Germany (4) Structural relationship of fullerenes, carbon nanotubes and graphite. Source: Oak Ridge National Laboratory Basically, by taking off one single layer of graphite, graphene is obtained. The carbon atoms in graphene are bound within a plane by chemical bonds into an array comprised of six-membered rings (benzene rings). Graphene is also closely related to carbon nanotubes and fullerenes. By stacking layers of graphene, the well known three dimensional graphite structure is obtained. Carbon nanotubes are formed by rolling up graphene sheets. And by adding five-membered rings it is possible to form fullerenes, football shaped structures, of which the most prominent one is the Buckminsterfullerene C60. The picture (from a presentation of Oak Ridge National Laboratory) illustrates the structural relationship of fullerenes, carbon nanotubes and graphite (from left to right) which are all based on graphene as building block. History of the graphene discovery Graphene, the miracle material, has come a long way. For a long time, scientists believed that such a two-dimensional structure would be unstable and roll up, as observed in the 1990s with carbon nanotubes and fullerenes. Only as late as in 2004, two Russian-born scientists, Andre Geim and Konstantin Novoselov of the University of Manchester in the UK,