Introduction

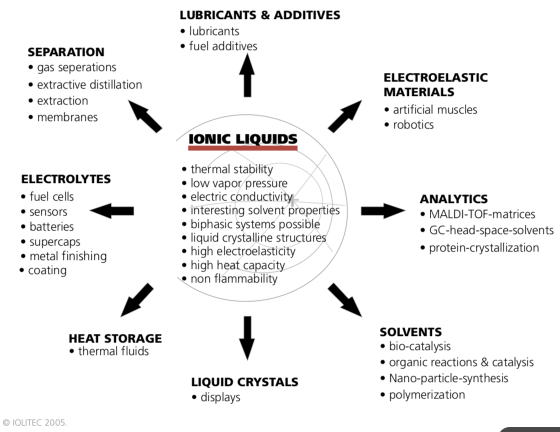

In the last 20 years ionic liquids, a new class of solvents, have gained increasing awareness in the scientific community. Numerous potential applications are described in the literature and a couple have already reached commercial stage. These include solvents in analytical applications, sensors and supercapacitors in electrochemical applications, and in chemical synthesis and catalysis, nano particle synthesis and as solvents for organic reactions. For textile applications, ionic liquids are still in laboratory stage, and in some cases they have reached pilot stage.

There is abundant literature available on the topic of ionic liquids in textile applications. Potentially they are considered as „green“ solvents. In this short article, only selected examples are cited. For readers who are interested in a comprehensive summary, the author refers to the excellent review article on the published literature of ionic liquids for textile application, recently published by Meksi & Moussa1.

To read the full article, please login. The full content of this article and all premium articles is available exclusively for site members.

Site membership is free. If you are an existing user, please login. New users may register below.