Greenpeace puts pressure on outdoor brands to phase out fluorocarbon chemistry

Greenpeace increases the pressure on leading outdoor brands to phase out fluorocarbon chemistry, by releasing a study which connected hazardous chemicals to outdoor articles found in the German, Swiss and Austrian retail market[1]. These markets are the most sensitive markets in the world with regard to awareness of environmental issues.

Greenpeace increases the pressure on leading outdoor brands to phase out fluorocarbon chemistry, by releasing a study which connected hazardous chemicals to outdoor articles found in the German, Swiss and Austrian retail market[1]. These markets are the most sensitive markets in the world with regard to awareness of environmental issues.

Critical findings of hazardous chemicals were found on outdoor textiles of major brands including Jack Wolfskin, The North Face, Marmot, Patagonia, adidas, Mammut, Mountain Equipment, Fjällräven, Kaikkialla, Vaude and others.

The culprits are fluorocarbon chemicals, more precisely per- and polyfluorinated chemicals (PFCs), which are associated with hydrophobic finishes to achieve water and soil repellency in outdoor textiles.

Spiegel Online[2] , the online version of Germany´s leading news magazine, took up the story immediately. Spiegel Online and Greenpeace both reach a large audience which will raise the awareness of the general public.

The study included 14 outdoor articles which were examined in 2 independent testing laboratories. The labs tested for PFCs and several other hazardous substance classes which were found as well in some of the articles. PFCs are considered as priority class of compounds in the detox campaign of Greenpeace.

According to the study, PFCs were found in all 14 articles (details see table below), even in the jacket of the Greenpeace activist, and even on two Bluesign labeled articles. Bluesign is one of the strictest eco label in the industry. Most items, however, are below the Bluesign and Oeko-Tox 100 limits for fluorocarbons which are shown in table 3.

Table 1: Fluorocarbons found in outdoor articles in Germany, Austria and Switzerland:

*in μg/m2, abbreviations: PFOA – perfluorooctanoic acid , PFCA-perfluoro carboxylic acids, FTOH – fluoro telomere alcohols , FTA – fluortelomere acrylate.

***number was revised in the report, in English version shows a lower number than German version, only 5.39 for PFOA

Remarks: PFCA (Cn) is a substance class that includes long chain compounds such as PFOA(C8) and short chain compounds such as PFHxA (C6). FTAs can be converted to release PFCAs, including PFOA. FTOH (sum) also includes short chain fluoro carbons such as 6:2 FTOH. Details of the individual PFCAs and FTOHs are given in the Appendix of the Greenpeace report.

Besides outdoor articles, water and soil repellent finishing is frequently applied in the manufacturing of uniforms, workwear, upholstery, awnings, linen and carpets.

Besides outdoor articles, water and soil repellent finishing is frequently applied in the manufacturing of uniforms, workwear, upholstery, awnings, linen and carpets.

Long-chain perfluoroalkyl acids (PFAAs) are considered as the most critical components, especially perfluorooctyl sulphonate (PFOS) and perfluorooctanoic acid (PFOA), which are used in the manufacturing of polymers.

These compounds are used to achieve water and soil repellency finish on textiles, due to their hydrophobic and oleophobic effects.

The good news is that PFOS, a banned substance in the EU, was not found in the outdoor textiles tested by Greenpeace.

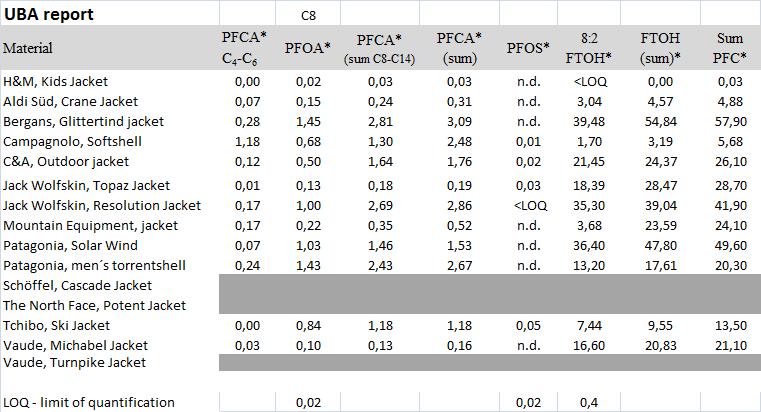

German UBA study

Earlier this year Greenpeace revealed another study of the German Umweltbundesamt (UBA, a federal agency in Germany for environmental affairs) which even found the banned PFOS in outdoor jackets of C&A, Jack Wolfskin and Tchibo, however, in very low quantities near detection limits of the analytical method[3]. At such low values, it cannot be excluded that the values could be also due to laboratory artefacts, preparation of samples, contaminations or ubiquitous prevalence rather than from a water repellent finishing.

In the UBA study, some of the 16 tested outdoor articles reached high levels of PFCs, and all articles contained PFCs.

Greenpeace requested the release and published the study on their website[4]. The study included Tchibo, Aldi Süd, H&M, C&A, Bergans, Campagnolo, Jack Wolfskin, Mountain Equipment, Schöffel, The North Face, Vaude and Patagonia.

Remarkably, according to the UBA report, the jackets were labeled as fluorocarbon free and carried the Bluesign label, one of the strictest environmental standards. However, many of the brands tested in the study are not members of Bluesign. Further clarification on this point would be required.

Even more remarkably, the second lowest was from Aldi, a German discount supermarket, with PFC levels far below brands such as Jack Wolfskin, Bergans and Patagonia. The kids jacket of H&M had by far the lowest values of PFCs measured, actually by an order of magnitude, according to this study.

The following table give an extract of the data. The complete data can be found in the UBA report[4]. In the report, the data of some brands were blackened, namely Schöffel, The North Face and Vaude. Greenpeace claims that the brands have requested to blacken the data.

In this study, many of the higher total PFC values are mostly due to long-chain FTOHs, especially 8:2 FTOH, as table 3 shows.

Table 2: Fluorocarbons found in outdoor articles according to UBA research report

*in μg/m2, abbreviations: as in Greenpeace table above, 0.00 means in all underlying components the rating was n.d. (not detected).

G-STAR even above legel limits

While in the above discussed tests the legal limit of PFOS was never exceeded, in a further test Greenpeace found PFOS concentrations significantly above legal background levels in outdoor textiles of G-STAR, a member of ZDHC, with values of 5.86 μg/m2 on gloves and 3.65 μg/m2 on a jacket for PFOS[5].

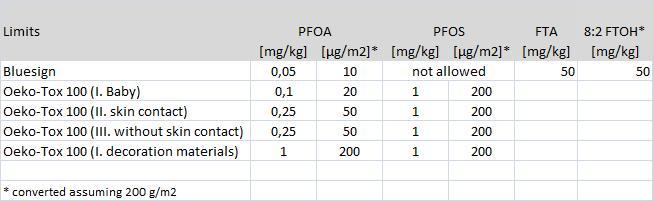

Discussion of limits for fluorocarbons

Table 3 shows limits used in important textile eco labels, Bluesign and Oeko-Tox 100.

Table 3: Fluorocarbons limits in important eco labels in the textile industry

In the Bluesign and Oekotox 100 limit the units for PFOA are given in mg/kg, however Greenpeace has used μg/m2. Therefore, the data in the Greenpeace report are not directly comparable. Assuming a fibre weight per area of 200 g/m2, the data can be converted to make it somewhat comparable.

From the data it is clear that the found values are far below the limits of Bluesign and Oekotox 100; in the UBA report the measured levels of PFOA is approximately 1/10 of Bluesign levels. Greenpeace requested to set a much stricter limit of 1 μg/m2 for PFOA, in analogy with the legal limit in the EU for PFOS.

Furthermore, it is surprising that Oeko-Tox 100 uses different units for PFOS and PFOA. Considering that PFOS is a banned substance, the limit (currently 1 μg/m2) should be at the analytical detection limit. However, according to UBA, the level of detection of their analytical method is considerably below this limit. The limits, therefore, seems historical and could be subject to reconsideration.

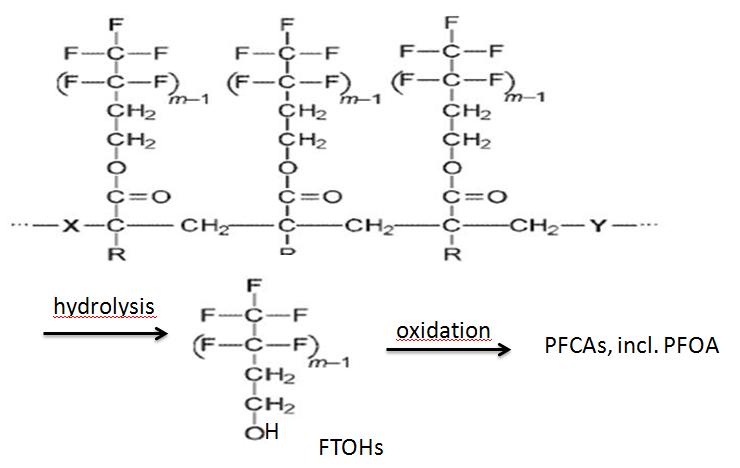

Another point of concern is that PFOA is not only a manufacturing or processing byproduct, or an ubiquitous impurity. PFOA is also released over time due to degradation the fluorocarbon polymer in the environment. The fluorocarbon finish is an ester of FTOHs, which would release after hydrolysis fluorotelomer alcohols (FTOH), including 8:2 FTOH, and after oxidation of the alcohol it would generate PFCAs, including the critical component PFOA. Therefore, much higher amounts of PFOA can be eventually released after degradation in the environment. It is known that such polymers degrade in the soil and yield PFOA and related persistent compounds[6,7]. The focus on PFOA as detected low level impurity on new outdoor textiles may not reveal the full of the problem.

PFCs do not occur naturally in the environment. They are used in many applications, including water and soil repellency finishes in functional textiles.

In particular, PFOS and PFOA are often discussed as problematic chemicals. PFOA and PFOS are both C8 PFCs. That means that they have both 8 carbon atoms in their chemical backbone carrying F substituents (in total they have more carbon atoms).

The following table shows the most important C8 fluorocarbon chemicals.

|

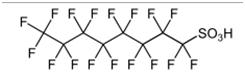

PFOS[9] (Perfluorooctanesulfonic acid) |

|

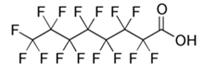

PFOA[10] (Perfluorooctanoic acid) |

|

8:2 fluorotelomer alcohol, (8:2 FTOH), degrades environmentally to PFOA |

Perfluorooctanesulfonic acid (PFOS), is a man-made fluorosurfactant and global pollutant. PFOS was the key ingredient in Scotchgard, a fabric protector made by 3M, meanwhile withdrawn from the market. It is banned in the EU since 2008. PFOS is persistent, bioaccumulative and toxic to mammalian species.

Perfluorooctanoic acid (PFOA) is used in the manufacture of widely known consumer goods as Teflon and Gore-Tex. PFOA has been manufactured since the 1940s in huge industrial quantities. It is also formed by the degradation of precursors, such as some fluorotelomers.

PFOA is highly persistent in the environment. It is a toxicant and carcinogen in animals. PFOA has been detected in the blood of more than 98% of the general population in the low quantities (parts per billion range).

For decades the chemical industry thought that fluorocarbons were inert chemicals and not hazardous. However, after receiving data on the global distribution and toxicity of PFOS, the key ingredient in Scotchguard, the United States Environmental Protection Agency (USEPA) began investigating perfluorinated chemicals more thoroughly. Research on PFOA then demonstrated its ubiquity, animal-based toxicity, and some connections with human health parameters and potential health effects.

In 2000, 3M announced the phase-out of the production of PFOA, PFOS, and PFOS-related products.

After C8 fluorocarbons have been identified as trouble-makers, shorter chain fluorocarbons, such as C6 fluorocarbons (the C6 compound comparable to PFOA would be PFHxA – perfluorohexanoic eacid), have been discussed frequently as alternative.

The next question is: are the short-chain fluorocarbons safe? In this context, Dr. Philippe Grandjean of Harvard School of Public Health commented on the question whether C6 would be a sustainable alternative. He said[11] “PFHxA, the C6 equivalent to PFOA, is a persistent material but may not bio-accumulate in humans as much as PFOA. On the other hand PFHxS, the C6 equivalent to PFOS, is also persistent and bio-accumulates just as much…. Most PFCs are potentially persistent in the environment and many bio-accumulate, including some which have carbon chains which are shorter than 8”.

This means it is questionable whether C6 fluorocarbon chemistry would be a sustainable alternative to C8 chemistry.

ZDHC brands committed to phase out hazardous chemistry

After Greenpeace started the detox campaign in 2011, major apparel brands were inspired to initiate the zero discharge of hazardous chemicals programme (ZDHC). We have reported about the progress earlier[12]. In this programme, the ZDHC brands have committed to phase out hazardous long-chain fluorocarbon chemistry.

In the roadmap to ZDHC document[13], the project is defined

“P05 – water repellent chemistry: confirm or set timelines for the elimination of products that are associated with PFOA and PFOS by replacing long chain (C8) fluorinated water repellent chemistry with alternative technologies”

The ZDHCs annual report 2012 stated in this context[14]

“we are focused on replacing C8 fluorinated water repellent chemistry..with alternative technologies including short-chain fluorochemical water repellents”

and further the annual report says

“confirmed or set timelines for the phase out of C8 chemistry no later than January 1, 2015”

But sometimes one has to read between the lines. Strictly speaking, the commitment of the ZDHC brands means that C8 fluorocarbon chemistry would still be considered as acceptable for oil/soil repellent functional textiles, since only water repellency is mentioned. Also, short-chain PFCs are explicitly mentioned as a viable alternative, according to the ZDHC brands point of view.

Positioning of German outdoor brands

In Germany, outdoor brands organized in BSI (Bundesverband der Deutschen Sportartikel-Industrie e.V.) are more progressive and have committed to a exit from PFCs[15].

In Germany, outdoor brands organized in BSI (Bundesverband der Deutschen Sportartikel-Industrie e.V.) are more progressive and have committed to a exit from PFCs[15].

Meanwhile, in a press announcement[16] Jack Wolfskin, the leading German outdoor maker, who was the first outdoor brand to join the ZDHC project[17], announced to phase out all fluoro chemistry till 2020 and committed for more transparency across their supply chain. A co-operation with Helmholtz-Zentrum Geesthacht (Zentrum für Material- und Küstenforschung) and Hochschule Fresenius should carry out the necessary application research to support this endeavour.

Jack Wolfskin is leading the industry with this initiative. They are the only outdoor brand pushing ahead progressively in this direction. It is very likely that eventually other will follow.

The ZDHC report on durable water repellents (DWRs)

The ZDHC project was initiated by leading brands to address the concerns raised by the Greenpeace detox campaign [13]. Some of the brands tested in the Greenpeace outdoor study are active member of ZDHC.

Meanwhile, a comprehensive ZDHC project report on durable water and soil repellent chemistry (DWRs) can be found on the website of the ZDHC project[18]. It is not clear at all who are the authors of this “research report”; possibly the ZDHC report was influenced by the Outdoor Industry Association (OIA)[19].

We were surprised that in the report the main focus was on short-chain fluorocarbon alternatives and largely restricted to already commercially available products, but unfortunately the report does not adequately consider alternative, promising technologies from research & development stage. We will elaborate in subsequent articles what such alternative technologies could be.

The ZDHC “research report” is basically a compilation of the already known status quo. Apparently the main source for information for the ZDHC “research report” was the internet and the chemical industry, respectively specific suppliers named in the report, though their product brochures.

It is already clear that Greenpeace will not accept short-chain fluorocarbons as alternative, since Greenpeace´s outdoor study [1] clearly mentioned that the short-chain fluorocarbons are classified as persistent chemicals with potentially harmful side-effects.

It is also questionable that the restriction in the commitment to phase out C8-fluorocarbons only for water repellency, but not including oil/soil repellency, would be a sustainable way into the future.

We would have preferred to adopt a more forward looking approach, including a long term vision. Such a vision has to set tough targets and should endorse technologies with potentially more attractive environmental impact. For a status quo analysis the conservative approach in the ZDHC project report may be acceptable. However, what is really needed is a vision for 2020 and a more specific action plan for phase out. The targets, in our opinion, should be far more ambitious, to push the incumbent players in the chemical industry out of their comfort zone.

It is disappointing that the ZDHC research report fails to address a clear vision, while primarily relying on product brochures of suppliers.

The vision cannot be to replace C8 by C6 fluorocarbon chemistry, without complete understanding what is the hazardous potential of C6. C4 and C6 fluorocarbon compounds are also persistent in the environment, a fact which is acknowledged by the ZDHC annual report [14] as well as in the DWR report [18].

The vision should be to avoid all hazardous chemistry.

Such a vision could include, for example, to phase out all hazardous chemistry until a specific deadline and replace by alternative technologies, or, if that should not be possible, to reconsider the performance level, in particular for outdoor articles.

We think that several factors are still delaying real progress, such as the ongoing influence from chemical industry experts and lobbyists (by their own words, the ZDHC project team used product brochures as a main source of information). The chemical industry might try to preserve the status quo and use ZDHC as a marketing channel to promote their product offers and gain market share. Also, the dramatic reduction of R&D capabilities in some of the chemical industry suppliers, and small to medium size structures of many suppliers, will make it an enormous challenge to achieve a substantial breakthrough of technology. Therefore, the involvement of independent specialists, academics, and open innovation concepts are vital, in our opinion.

The targets and solutions should be more open for change. As long as the status quo in requirements is preserved, nothing will change. As long as another potential problem is a preferred solution (C6 instead of C8 fluorocarbon chemistry), while considering new, alternative technologies only as an option on the sideline, nothing will change.

We should ask: do we really need all these technical features in outdoor articles? Questions like: why does a outdoor jacket for walking in the rain require oil repellency?

Therefore we call upon the ZDHC project leaders to include independent expertise including academics, monitor the progress in science and catalyze real progress by setting real tough targets. If the ZDHC will not do this, NGOs such as Greenpeace will keep up the pressure.

No doubt, the development of alternative technologies meeting performance as well as toxicological and environmental requirements, is challenging. However, to operate in a challenging environment should not stop us from doing it.

“We choose to go to the moon in this decade and do the other things. Not because they are easy, but because they are hard.” John F. Kennedy

Outlook

In this article we have discussed reports of Greenpeace and the German Umweltbundesamt (UBA) on hazardous fluorocarbons found in outdoor articles, and the progress of the ZDHC brands towards elimination of such hazardous chemicals.

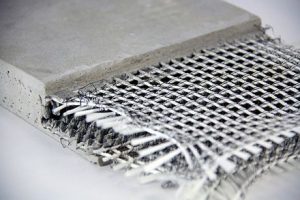

In the next article “Technical background of water and soil repellent textiles, and alternatives for the future” we will discuss the technical and scientific aspects of water and soil repellent finishing, and will look at alternatives for the future, in particular more sustainable technologies and chemistries.

To be continued

[1] Greenpeace Report: “Chemistry for any weather”

[2] Kwasniewski,N., Spiegel Online : „Belastete Outdoor-Kleidung: Zurück zur Chemie“

[5] Greenpeace 4/2013, „Schadstoffe in G-Star Produkten“

[6] Parsons JR, Sáez M, Dolfing J, de Voogt P. Rev Environ Contam Toxicol. 2008;196:53-71. “Biodegradation of perfluorinated compounds”

[7] Washington JW, Ellington J, Jenkins TM, Evans JJ, Yoo H, Hafner SC, Environ Sci Technol. 2009 Sep 1;43(17):6617-23. Degradability of an acrylate-linked, fluorotelomer polymer in soil

[8] Schindler,W. & Hauser, P. “Chemical Finishing of Textiles”, Woodhead Publishing, 2004

[12] Zero discharge programme in textile industry moving to version 2, Slow progress in the Greenpeace detox campaign, More challenges in the Greenpeace detox campaign

[13] http://www.roadmaptozero.com programme documents

[14] Annual report 2012 of Zero Discharge of Hazardous Chemicals programme

[18]ZDHC project report, unknown authors: “Durable water and soil repellent chemistry in the textile Industry – a research report”

@Greenpeace puts pressure on outdoor brands to phase out fluorocarbon chemistry #Detox http://t.co/jtIbny5pRh

Pingback: Technical background of water and soil repellent textiles