Sustainable colouration concepts. Part I. Colouration without dyes

This article series will discuss latest trends and future perspectives in colouration technologies. The first part is about colouration without dyestuffs like nature does it. Dyeing and dyes would no longer be required to create colour effects – colouration without dyes.

This article series will discuss latest trends and future perspectives in colouration technologies. The first part is about colouration without dyestuffs like nature does it. Dyeing and dyes would no longer be required to create colour effects – colouration without dyes.

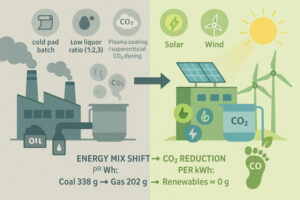

In recent years the people have been discussing a lot about sustainable textile coloration concepts. The fashion industry and retail brands have started an important initiative towards “zero toxics discharge 2020”, initiated by Greenpeace and supported by big names such as Nike, adidas, C&A, H&M, Puma and others. But not only toxic chemicals, which are major concern of the Greenpeace project, are an issue. A great deal of other chemicals, often not even properly toxicologically assessed, are released to the environment. On the other hand, in big parts of the world, people have lack of clean fresh water which is consumed for agriculture and industry. Textile processing plays a big part in this. During textile processing the effluent is contaminated by chemicals used in the processing (e.g. measured by COD value of the discharged effluent). Zero discharge concepts – recycling and effluent treatments – are implemented in some parts of the industry to avoid contaminated effluents, but usually this happens only when by processing houses are forced by legislation of in case of severe water constraints.

To read the full article, please login. The full content of this article and all premium articles is available exclusively for site members.

Site membership is free. If you are an existing user, please login. New users may register below.