The textile supply chain and jeans production in China

The video (in German language) shows the manufacturing of jeans made for well known brands in Guangdong province of China. It was broadcasted on the German television channel Phoenix just a few days ago.

The video (in German language) shows the manufacturing of jeans made for well known brands in Guangdong province of China. It was broadcasted on the German television channel Phoenix just a few days ago.

One particular example was kik, a German discount retailer. Kik´s retail selling price in Germany for a pair of jeans is 9.99 €. The journalists tracked down the origin of the jeans to a manufacturer in Guangdong in China and found out that the manufacturer in China sells a pair of jeans for roughly 3 € to a trader.

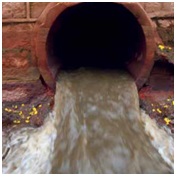

The video shows critical issues of poor safely standards in working conditions and environmental pollution for dyeing and finishing, for example bleaching with hypochlorite by manual spray applications in the basement of a Chinese factory shop. The deeply coloured effluent on the video does not really look like state of the art in effluent treatment either.

The retailers typically blame the Chinese authorities´ responsibility for lack of implementation of safe standards, and say their only alternatives for sourcing jeans are Chinese, Indian or Bangladeshi suppliers, for cost reasons, and they would basically all operate in a similar way. And the Hongkong Chinese entrepreneur who operates the manufacturing plant says he is squeezed so much by the buyer, he can´t afford any investments to improve the conditions, and he can´t afford to pay more to his workers who earn not more than 250 € per month.

Well, of course, if the target selling price in the retail shop in Germany is below 10 €, there would not be much space to the upside in cost, and no fat margins for the traders and manufacturers either. But the consumer´s expectation to buy a pair of discount jeans for such low prices, and the lack of consumer awareness for the issues is only one part of the problem.

The same factories appeared to be producing for big brands as well. Names such as H&M, one of the brands who committed on the Greenpeace detox project, and New Yorker were mentioned. The video does not really give the impression that for these orders higher standards would be applied, although these brands sell their jeans usually for much higher prices.

From the video is obvious that it is a long way to go in making our textile supply chain safe, without damaging the health of the workers and without polluting the environment.

We already pointed out in a report last week potential environmental and safety issues from the dyeing of jeans using the dyestuff indigo, for which a detailed scientific evaluation is ongoing.

Once the consumer awareness is improved by education and public campaigns, such as the Greenpeace detox campaign, more and better standards would be implemented and constantly monitored by brands and regulators. We can´t afford any longer a “don´t ask don´t tell“ attitude.

interesting report. I wonder how much margin the traders in Hongkong make with this. What value does the trader add to the product ?

To cut off the trader would surely give a relief for the manufacturer and the brands.

The shame of this is that the look of “worn” jeans is artificially applied via bleaching and abrasion. If these jeans were sold without the treatment, they’d probably fall apart before they were able to acquire a look of being worn. That’s probably because they’re made of short-fiber cheap cotton with no strength, in contrast to the old Levi’s, Finck, or Oshkosh made-for-the-job-and-not-a-fashion-statement garments. One could easily get 10 years of wear on the job with the old brands–I suspect that the Chinese merchandise doesn’t survive a year.

The horrible thing is that the cheap garbage has pushed out the quality merchandise in the market–and it’s happening on all fronts. I can’t think of anything more antithetical to the German consciousness, yet here we are! What’s next, Daimler to manufacture Trabant copies?

Where is the logic in all of this?

i want to be your reseller in Kenya.