Latest technological developments in the digital printing space for textile

Digital printing is driven by technology and innovation. It is presently one of the most exiting segments in the whole textile processing.

Digital printing is driven by technology and innovation. It is presently one of the most exiting segments in the whole textile processing.

A variety of new printing systems and consumables for digital printing have been launched during ITMA 2015 in Milan, Italy, the world’s most established trade exhibition for textile and garment manufacturing technologies.

Industrial single pass digital printing

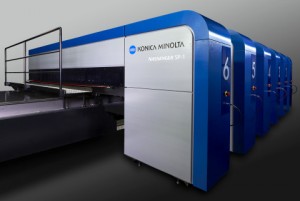

The most significant development is perhaps the launch of three new industrial single pass digital printers to join MS-LaRio in the segment of high productivity ink jet printers. The new printers are Konica Minolta Nassenger SP-1, Atexco Vega One and SPGPrints Pike.

MS´s LaRio, launched in 2010, employs Kyocera printheads, a resolution of 600×600 dpi, a maximum printing width of 3.2 meters wide at speed of up to 75 linear meters per minute with 4 colours and 35 m/min with 8 colours. MS also announced during ITMA that they sold more LaRio printers to various customers including Sanitars Cotton Line (Italy), SCR (Italy), Shrijee (India) and Ruyi (China).

SPGPrints new single pass digital textile printer flagship model Pike isbased on Fujifilm Samba print heads. The new printer has a higher resolution of 1200×1200 dpi, a maximum printing width of 1.85 meters wide, delivering a typical productivity of 40 linear meters per minute. Pike employs Archer Technology to provide a higher printing distance (4mm) from the nozzle plate necessary for digital textile applications, enabling a wide range of fabric textures. SPGPrints announced during the ITMA exhibition that they sold the first Pike single-pass digital printer to KBC Fashion, based in Lörrach, Germany.

The Japanese company Konica Minolta announced the NASSENGER SP-1, a single-pass ultra-high speed, high productivity and high resolution digital printer. The new single pass printer system is based on newly developed print heads that can eject smaller ink droplets. It uses proprietary ink ejection control technology, which enables adjustment of ink droplet sizes, thus achieving higher-quality reproduction of fine patterns and colour gradients. For minimized downtime, the model is equipped with functionality that compensates for errors detected by print head nozzle sensors, and able to adjust density uniformly for each colour on all of the print head modules, thanks to density correction functions using image sensors.

The Chinese company Atexco (Hangzhou Honghua Digital Technology) , also launched a single pass digital printer during ITMA 2015, the Atexco Vega One which is also based on Fujifilm Samba print heads.

Digital inks

Digital inks are a major cost factor in operating costs of ink jet printing on textiles. After the ink jet printers have reached productivity levels comparable or higher than screen printing, the comparably high ink cost are still a limiting factor for cost efficient digital printing. However, ink prices have already come down due to more competition and open systems. Ink margins are still high, process are far above material cost of the inks. Digital printing companies make more money with consumables such as inks, rather than with printing hardware.

The dyes contents in inks, for example in the case of reactive dyes inks, is only 10-15%, and considering that same colorants are used as in conventional printing, but in a different, more sophisticated liquid formulation, it is obvious that prices still have a long way to go down. Also, the high margins have invited more players in India and China to start an ink business which will drive down process further.

One way to stop the price erosion would be to close the open systems, to make it harder for textile printers to change the ink systems. Traditionally, Japanese companies have preferred closed systems, for example Konica Minolta covers all aspects of the printing system: the print head, printer, ink and software are all developed by them. On the other hand MS LaRio is an “open system” running with inks for various suppliers, including digital inks by SPGPrints, by the way.

The cost of head replacement is a major concern for buyers in fixed-array machines. SPGPrints proposes an arrangement in conjunction with Pike® inks, in which any faulty printing heads returned would be replaced free of charge. However, this may be a show stopper for competitive inks and would reduce the bargaining power for ink buyers. A good marketing effort by SPGPrints, so to speak.

Pigment ink digital printing

In textile printing, 50% of colorants are pigments, but in digital printing the share is much less. The reason is the risk of nozzle clogging caused by pigment particles. Now, technological improvements in pigment ink formulations and printing technology, digital printing with pigment inks are getting more and more interesting. Pigment printing only require a heat-fixation step for post treatment, and therefore provides an eco-friendly process with reduction in water consumption and waste.

Some new products that were launched at ITMA 2015 included Kiian´s Digistar K-Choice, a new pigment ink for the Kyocera heads, Velvet jet´s new pigment printing solution for digital textile printing, Fujifilm Imaging Colorants new Pro-JET TX pigment based ink for high speed textile printing with dry heat fixation technology with allows for waterless fixation.

Also, some machines exhibited at ITMA 2015 exhibition were running on pigment ink successfully, for example the Durst Alpha 330, Colorjet Metro. Miyakoshi MTP Series, Kornit Allegro and MS – JPK Evo indicating the evolution of pigment inks to suit high speed production machines.

More interesting insights in the latest innovative developments in the digital printing space are covered in the ITMA blog and the blog of Inkjet Forum India after the 2015 ITMA trade exhibition in Milano, Italy.

Thanks for such a latest technological developments printing ink, its really very useful for more update.

Printing Ink Manufacturers in India | Speciality Coatings Manufacturer

nice information given as it gives important information about the printing ink manufacturing, for more information about the same see here Holographic Embossing Lacquer Manufacturer | Air Drying Lacquer Manufacturer